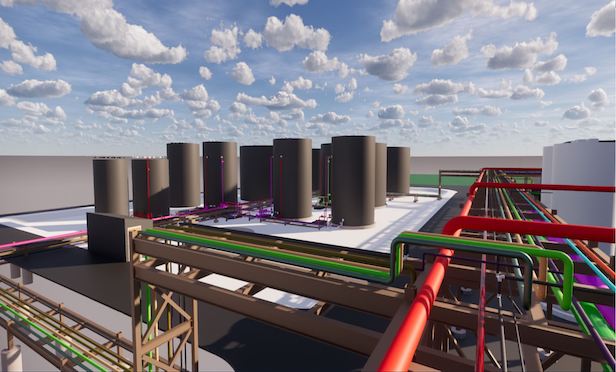

A rendering of the nation's first commercial-scale plastics to fuel plant in Ashley, IN.

A rendering of the nation's first commercial-scale plastics to fuel plant in Ashley, IN.

ASHLEY, IN—Brightmark Energy of San Francisco has commenced construction on what it terms as the nation's first commercial-scale plastics to fuel facility here.

The company says the Ashley facility will be the first of its kind to take mixed waste single-use plastics and convert them into usable products at commercial scale. The facility will convert approximately 100,000 tons of plastics into more than 18 million gallons a year of ultra-low sulfur diesel and naphtha blend stocks and nearly six million gallons a year of commercial grade wax each year.

BP will purchase the fuels produced by the facility and AM WAX will purchase the wax.

When fully operational, the 112,000-square-foot plant will employ a total of 136 full time manufacturing workers in Northeast Indiana.

Last month, Brightmark closed a $260-million financing package for the construction of the plant, which includes $185 million in Indiana green bonds, which were underwritten by Goldman Sachs & Co. As part of the financing closure, Brightmark became the controlling owner of RES Polyflow, the Ohio-based energy technology company that innovated the process for converting plastics directly into transportation fuel and other products, the company states.

Brightmark Energy CEO Bob Powell, who presided over yesterday's groundbreaking event, says there is a need for paradigm-shifting recycling technologies, such as the process that will be applied in the new plant.

“This sustainable technology directly addresses an acute problem facing our nation: more than 91% of the 33 million tons of plastic produced in the US each year is not recycled,” Powell says. “These products end up sitting in landfills for thousands of years or littering our communities and waterways. This technology offers a tremendous opportunity to combat a major environmental ill and create positive economic value in the process.”

Jay Schabel, president of Brightmark Energy's plastics division, said, “Brightmark plans to develop dozens of additional plastics-to-fuel facilities across the United States, and these new locations will all be anchored by the facility we're breaking ground on today here in Northeast Indiana. We're pleased to have this opportunity to offer a solution to the complex problems our nation faces around plastic pollution.”

© Touchpoint Markets, All Rights Reserved. Request academic re-use from www.copyright.com. All other uses, submit a request to [email protected]. For more inforrmation visit Asset & Logo Licensing.